Unser Leistungsspektrum reicht von einfachen teilautomatisierten Handarbeitsplätzen bis hin zu vollautomatisierten Systemen. Durch die Integration modernster Technologien in den Bereichen Kollaborative Automation, Sondermaschinenlösungen, Anlagenautomatisierung und Prozessautomatisierung schaffen wir effiziente und innovative Lösungen, die genau auf die Bedürfnisse unserer Kunden abgestimmt sind.

Im Zentrum unseres Handelns steht die Realisierung von Projekten, die eine nahtlose Integration von Sondermaschinen und Automationslösungen ermöglichen. Dabei legen wir besonderen Wert auf die Entwicklung und Implementierung von Strategien zur Anlagenautomatisierung, die die Effizienz steigern und gleichzeitig die Betriebskosten senken. Unsere Expertise im Bereich der Prozessautomatisierung ermöglicht es uns, komplexe Produktionsabläufe zu optimieren und die Produktivität signifikant zu erhöhen.

Die Schaltag Gruppe steht dafür, von der Konzeptphase bis zur Inbetriebnahme eng mit unseren Kunden zusammenzuarbeiten, um sicherzustellen, dass jede Sondermaschinenlösung perfekt auf die spezifischen Anforderungen zugeschnitten ist. Nach der Inbetriebnahme bleibt unser Engagement für hervorragenden Service bestehen, mit dem Versprechen einer schnellen und effizienten Reaktion auf alle Anfragen und Bedürfnisse unserer Kunden. Mit unserem umfassenden Angebot an Dienstleistungen im Bereich der Automationsanlagen setzen wir neue Massstäbe im Sondermaschinenbau und tragen dazu bei, die Produktionslandschaft unserer Kundschaft nachhaltig zu transformieren.

Für die Automation bieten wir die folgenden Dienstleistungen an:

PLC Software Engineering

- Grafische/Text-Programmierung (FUP / AWL und Graph 7)

- Siemens S5 – S7, SCL, C++, WinCC (TIA – Portal)

- B & R Automation Studio V4.x (Level: Qualified Partner)

- Sigmatek Lasal Motion Control, Service, Diagnose, Safety

(Level: Qualified Partner)

- Rockwell RS Logix

- Communication concept/bus system: Control, monitoring and field level

- Project management

- Anforderungsmanagement

- Konzepterstellung (Fertigungs-, Prüf-, Steuer, Sicherheitskonzepte…)

- Berechnungen/Simulationen

- Mechanisches und elektrisches Design

- Elektrische und mechanisches Konstruktion

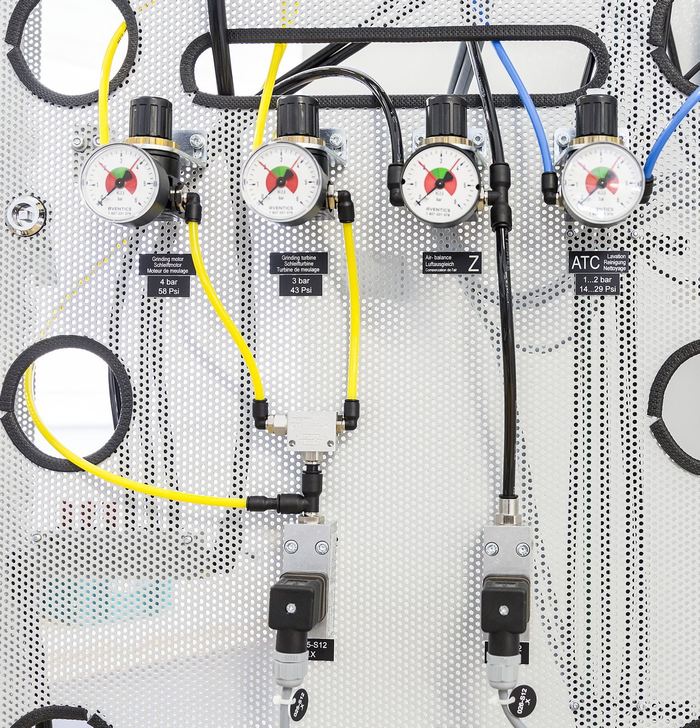

- Erstellen elektrisches und pneumatische Schema

- SW Erstellung

- Fertigung der Anlage mit Abnahme bei uns im Werk (FAT)

- Installation der Anlage (SAT)

- Inbetriebnahme

- Schulungen der Kunden

- After Sales Service

Sondermaschinenbau: Von der Konzeptentwicklung bis zum Aufbau

In der Konzeptphase werden in enger Zusammenarbeit die Anforderungen mit dem Kunden erarbeitet und das optimale Lösungskonzept ermittelt.

Dieses wird in den nächsten Phasen umgesetzt.

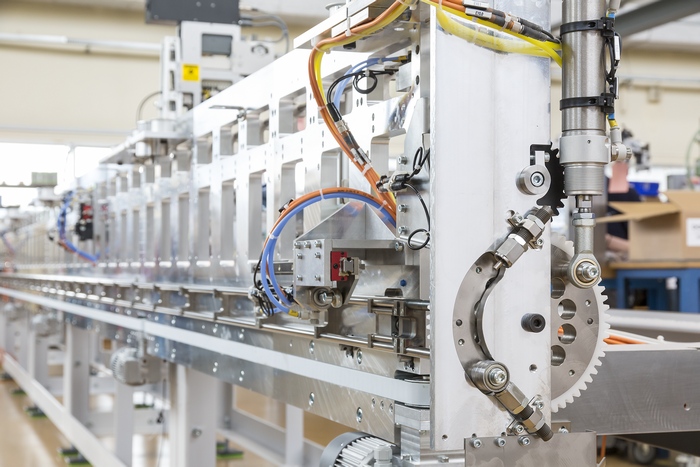

Basierend auf Profilsystemen oder Blechkonstruktionen bauen wir unter Verwendung von Transportbändern, Rundschalttischen, Antriebstechnik (Servos, Frequenzumrichter), Roboterarmen, Pneumatische und Hydraulische Systeme und viele weitere Komponenten Ihre Anlage auf.

Sondermaschinenbau: Integration moderner Technologien für präzise Qualitätskontrolle

Für die Qualitätskontrolle im Sondermaschinenbau verwenden wir fortschrittliche Kameras (Inspektionstechnik) und weitere Sensoren.

Die Steuerungssoftware basiert auf modernen SPS oder, wo notwendig, auf industriellen PCs. Die Visualisierung wird dabei durch eine breite Palette an Lösungen, vom einfachen Bediengerät bis zu komplexen PC basierenden Bildschirmen, abgedeckt. Auch kann die Einbindung in ein übergeordnetes System realisiert werden.

Sondermaschinenbau: Umfassender Service für Ihre Anlagen

Unsere professionelle Fertigung im Sondermaschinenbau wird, so weit möglich, in unserem Haus getestet und danach bei Ihnen in Betrieb genommen. Allfällige Optimierungen werden mittels Produktionsbegleitung umgesetzt. Dabei schulen wir das Bedien- und Wartungspersonal.

Unser Team steht danach für weiteren Support zur Verfügung, um eine störungsfreie Produktion zu gewährleisten.

Der Sondermaschinenbau ist in einer Vielzahl von Branchen von entscheidender Bedeutung, um spezifische Herausforderungen mit massgeschneiderten Lösungen zu bewältigen:

- Pharmaindustrie: In dieser hochregulierten Branche der Pharma sind Sondermaschinen unverzichtbar, um die strengen Anforderungen in Bezug auf Präzision, Reinheit und Dokumentation zu erfüllen.

- Verpackungsindustrie: Sondermaschinen sind auch im Bereich Packaging von grosser Bedeutung, wo sie individuell angepasste Lösungen für die Verpackung verschiedenster Produkte bieten.

- Medizintechnik (Medtech): Im Bereich Medtech werden hochspezialisierte Sondermaschinen benötigt, um Geräte und Instrumente herzustellen, die den strengen regulatorischen Anforderungen und hohen Präzisionsstandards entsprechen. Diese Maschinen sind entscheidend für die Produktion von Implantaten, diagnostischen Geräten und anderen medizinischen Hilfsmitteln.

- Erneuerbare Energien: Der Bereich der erneuerbaren Energien, insbesondere die Solarindustrie, erfordert Sondermaschinen zur Herstellung von Solarzellen und Solarmodulen. Diese Maschinen müssen in der Lage sein, Materialien präzise zu verarbeiten und zu handhaben, um die Effizienz und Leistungsfähigkeit der Photovoltaik-Produkte zu maximieren.

- Lebensmittelindustrie: Im Bereich der Lebensmittel entwickeln wir Sondermaschinen, die nicht nur auf spezifische Produktformate zugeschnitten sind, sondern auch höchste Hygienestandards erfüllen. Durch die Implementierung von Discrete Automation Technologien stellen wir sicher, dass die Sicherheit und Qualität der Lebensmittelproduktion durch präzise und effiziente Prozesse gewährleistet wird.

- Weitere Branchen: Die Flexibilität des Sondermaschinenbaus findet auch in anderen Industriebereichen wie der Robotik, Automatisierungstechnikund Elektronikindustrie Anwendung, wo spezialisierte Maschinen zur Optimierung von Produktionsprozessen beitragen.

Erfahren Sie mehr darüber, wie unsere innovativen Sondermaschinenlösungen auch Ihre Produktionsprozesse optimieren können. Kontaktieren Sie uns für eine individuelle Beratung und entdecken Sie die Möglichkeiten, die der Sondermaschinenbau für Ihr Unternehmen bereithält.

FAQ – Sondermaschinenbau

Was genau versteht man unter Sondermaschinenbau?

Sondermaschinenbau bezieht sich auf die Entwicklung, Konstruktion und Herstellung von Maschinen und Anlagen, die speziell auf die individuellen Anforderungen und Bedürfnisse eines Kunden zugeschnitten sind. Diese können von einfachen Handstationen bis hin zu vollautomatisierten Systemen reichen und umfassen Technologien wie Discrete Automation, Anlagenautomatisierung und Prozessautomatisierung, um effiziente und innovative Lösungen zu schaffen.

Welche Dienstleistungen bietet die Schaltag Gruppe im Bereich der Automation an?

Die Schaltag Gruppe bietet eine breite Palette an Dienstleistungen an, darunter Software-Engineering für SPS, grafische und Text-Programmierung, Projektmanagement, Anforderungsmanagement, Konzepterstellung, Berechnungen/Simulationen, mechanisches und elektrisches Design, Fertigung der Anlage, Installation, Inbetriebnahme, Schulungen und After Sales Service.

Wie gewährleistet die Schaltag Gruppe die Qualität und Effizienz der Sondermaschinen?

Die Qualität und Effizienz werden durch die Verwendung fortschrittlicher Kameras und Sensoren für die Qualitätskontrolle, moderne SPS-Steuerungssoftware oder industrielle PCs für die Steuerung, sowie durch umfassende Tests im Haus vor der Inbetriebnahme sichergestellt. Optimierungen werden mittels Produktionsbegleitung umgesetzt, und das Bedien- und Wartungspersonal wird geschult, um einen reibungslosen Betrieb zu gewährleisten.

Wie unterstützt die Schaltag Gruppe ihre Kundschaft nach der Inbetriebnahme der Anlagen?

Nach der Inbetriebnahme der Anlagen gehört ein hervorragender Kundenservice, einschliesslich schneller und effizienter Reaktion auf alle Anfragen und Bedürfnisse, zu unserem Angebot. Unser Team steht für weiteren Support zur Verfügung, um eine störungsfreie Produktion zu gewährleisten und bietet After Sales Service, um langfristigen Erfolg und Zufriedenheit zu sichern.

Sondermaschinenbau:

Sondermaschinenbau: